Raymond Mill

Application

Raymond mill is widely used in barite, calcite, potassium feldspar, talc, marble, limestone, dolomite, Ying Shi, lime, activated silica, activated carbon, bentonite, kaolin, cement, phosphorite, gypsum, glass, thermal insulation materials, etc. Moh's hardness is not greater than 9.3, humidity in the following 6% of the non-inflammable and explosive mineral, chemical, construction and other industries more than 280 kinds of materials, high fine powder processing. R type raymond mill finished particle size 80-325 mesh range of arbitrary adjustment, some materials up to 600 mesh.

Structure

The structure of the machine mainly consists of main machine, analyzer, blower, finished product cyclone separator, micro powder cyclone separator and air duct. Among them, the main machine is composed of frame, air inlet worm shell, shovel knife, grinding roller, grinding ring and cover.

Working Principle

When working, the material that needs to be crushed is added to the machine from the feed hopper on the side of the cover shell. It revolves around the vertical axis and rotates itself at the same time. Due to the role of centrifugal force during rotation, the grinding roller swings outward and presses tightly on the grinding ring, so that the blade scoops up the material between the grinding roll and the grinding ring. The purpose of crushing the material is achieved by rolling the roller.

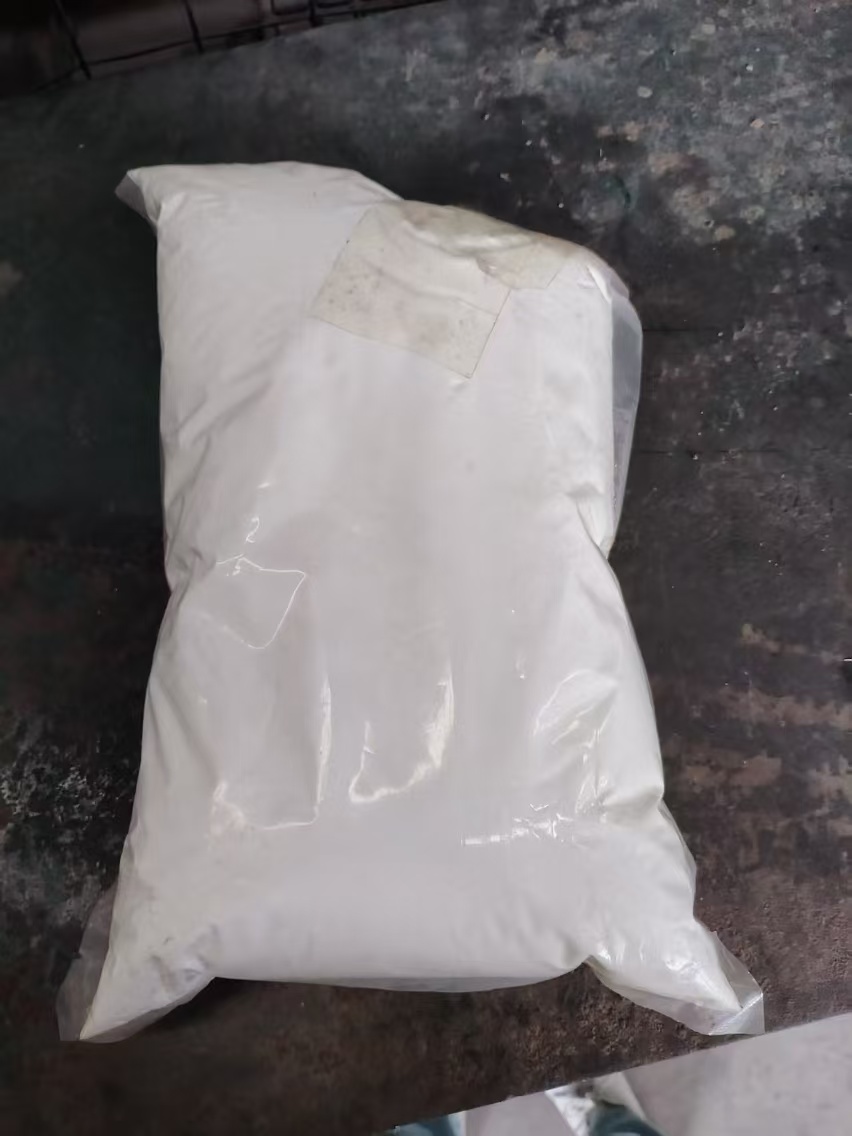

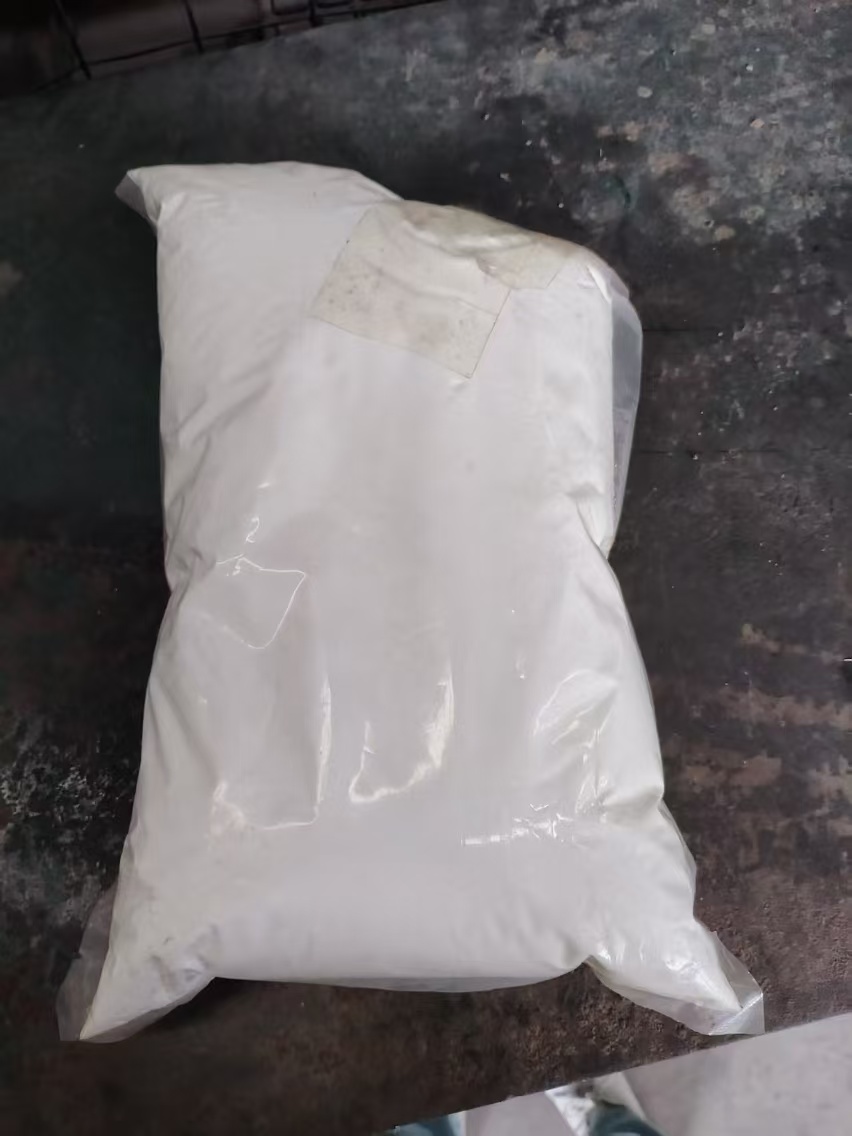

Calcium powder

Raymond Mill

Application

Raymond mill is widely used in barite, calcite, potassium feldspar, talc, marble, limestone, dolomite, Ying Shi, lime, activated silica, activated carbon, bentonite, kaolin, cement, phosphorite, gypsum, glass, thermal insulation materials, etc. Moh's hardness is not greater than 9.3, humidity in the following 6% of the non-inflammable and explosive mineral, chemical, construction and other industries more than 280 kinds of materials, high fine powder processing. R type raymond mill finished particle size 80-325 mesh range of arbitrary adjustment, some materials up to 600 mesh.

Structure

The structure of the machine mainly consists of main machine, analyzer, blower, finished product cyclone separator, micro powder cyclone separator and air duct. Among them, the main machine is composed of frame, air inlet worm shell, shovel knife, grinding roller, grinding ring and cover.

Working Principle

When working, the material that needs to be crushed is added to the machine from the feed hopper on the side of the cover shell. It revolves around the vertical axis and rotates itself at the same time. Due to the role of centrifugal force during rotation, the grinding roller swings outward and presses tightly on the grinding ring, so that the blade scoops up the material between the grinding roll and the grinding ring. The purpose of crushing the material is achieved by rolling the roller.

Calcium powder