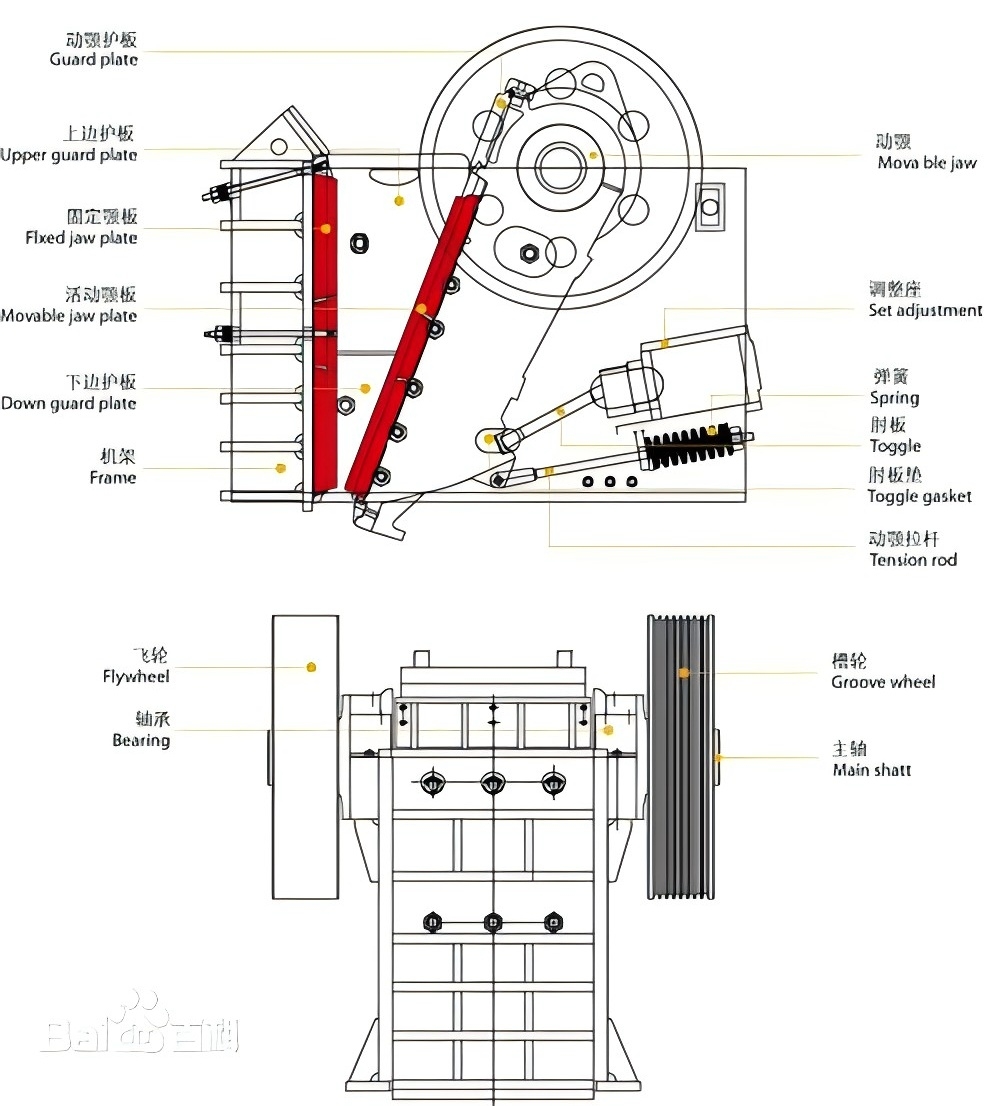

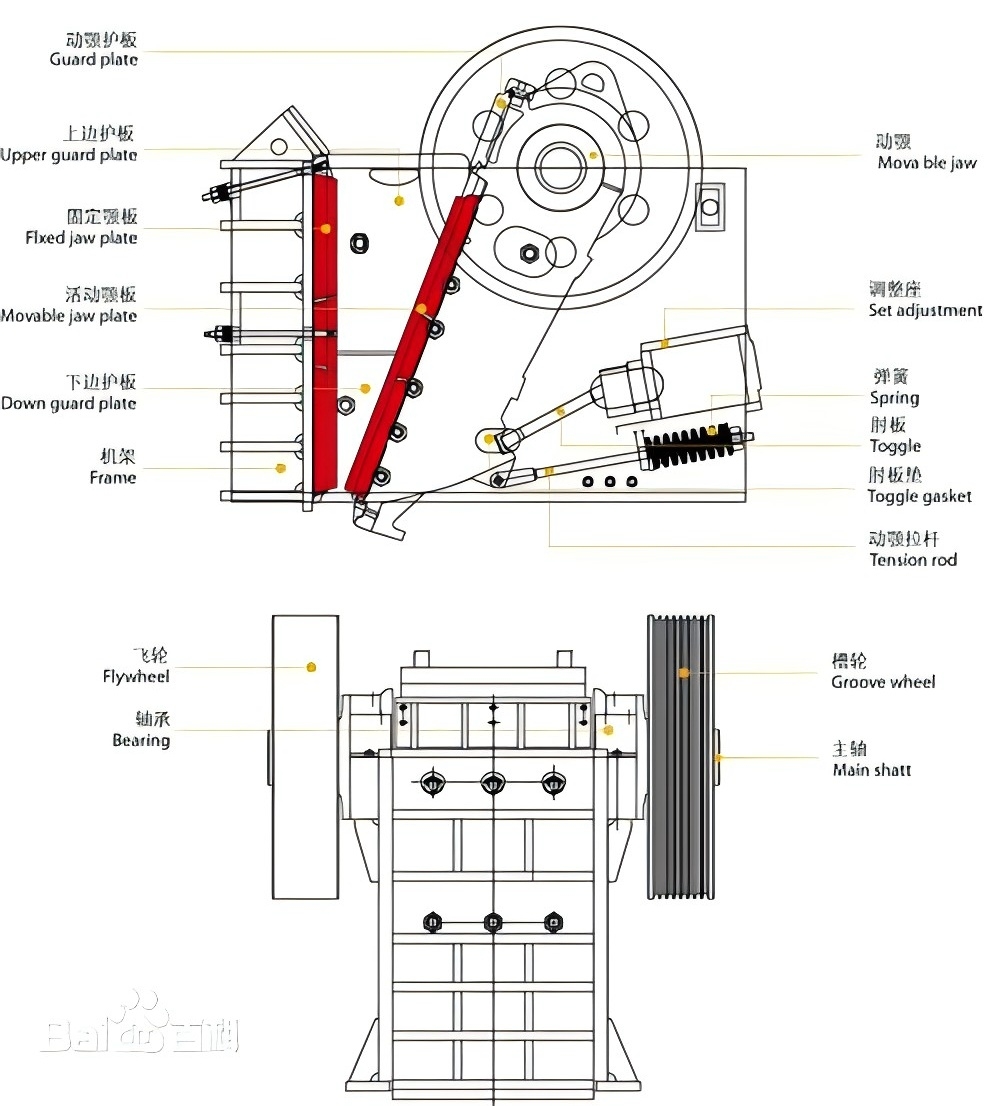

Jaw crusher consists of two jaw plates, the movable jaw and the static jaw, to simulate the movement of the two jaws of the animal and complete the crushing operation of the crusher. It is widely used in mining and smelting, building materials, highway, railroad, water conservancy and chemical industry for crushing various ores and large materials. The highest compressive strength of the crushed material is 320Mpa.

Jaw crusher is mainly used as coarse crusher and medium crusher in mining, building materials, infrastructure and other sectors. According to the width of the feed inlet, it's divided into large, medium and small sizes, over 600 mm for large-scale machines, 300-600 mm for medium-sized machines, less than 300 mm for small machines. Jaw crusher is simple in structure, easy to manufacture and reliable in work.

According to the different swinging ways of the movable jaw plate, the jaw crusher can be divided into three kinds: simple swing jaw crusher, complex swing jaw crusher crusher and comprehensive swing jaw crusher.

After the ore is crushed, the particle size becomes smaller, and the ratio of the particle size of the ore before crushing to the particle size after crushing is called crushing ratio. Crushing ratio is an important evaluation index of jaw crusher, which indicates that after the ore is crushed, the particle size is reduced by a multiple. There are several ways to calculate the crushing ratio as follows:

1. Using the maximum size of the ore before and after crushing to calculate the ratio, this calculation method is often adopted in China in the design of mineral processing plants, because the design should be based on the maximum size of the feed ore to determine the width of the jaw crusher feed opening.

2. Ratio between the effective width of the feed opening and the width of the discharge opening of the jaw crusher.

Note: The discharge size of some jaw crushers is not determined by the size of the discharge opening.

3. Calculating the average size of the ore before and after crushing, also known as the average crushing ratio.

Jaw crusher consists of two jaw plates, the movable jaw and the static jaw, to simulate the movement of the two jaws of the animal and complete the crushing operation of the crusher. It is widely used in mining and smelting, building materials, highway, railroad, water conservancy and chemical industry for crushing various ores and large materials. The highest compressive strength of the crushed material is 320Mpa.

Jaw crusher is mainly used as coarse crusher and medium crusher in mining, building materials, infrastructure and other sectors. According to the width of the feed inlet, it's divided into large, medium and small sizes, over 600 mm for large-scale machines, 300-600 mm for medium-sized machines, less than 300 mm for small machines. Jaw crusher is simple in structure, easy to manufacture and reliable in work.

According to the different swinging ways of the movable jaw plate, the jaw crusher can be divided into three kinds: simple swing jaw crusher, complex swing jaw crusher crusher and comprehensive swing jaw crusher.

After the ore is crushed, the particle size becomes smaller, and the ratio of the particle size of the ore before crushing to the particle size after crushing is called crushing ratio. Crushing ratio is an important evaluation index of jaw crusher, which indicates that after the ore is crushed, the particle size is reduced by a multiple. There are several ways to calculate the crushing ratio as follows:

1. Using the maximum size of the ore before and after crushing to calculate the ratio, this calculation method is often adopted in China in the design of mineral processing plants, because the design should be based on the maximum size of the feed ore to determine the width of the jaw crusher feed opening.

2. Ratio between the effective width of the feed opening and the width of the discharge opening of the jaw crusher.

Note: The discharge size of some jaw crushers is not determined by the size of the discharge opening.

3. Calculating the average size of the ore before and after crushing, also known as the average crushing ratio.